If you’re considering Ortho Tri-Cyclen as your contraceptive choice, it’s crucial to look into who manufactures it. Ortho Tri-Cyclen is produced by Janssen Pharmaceuticals, a subsidiary of Johnson & Johnson. This reputable company has a long-standing history in the pharmaceutical industry, specializing in a variety of medications, including hormonal contraceptives.

Janssen’s commitment to quality is reflected in their rigorous testing and manufacturing processes. Each tablet of Ortho Tri-Cyclen undergoes strict quality control measures to ensure safety and efficacy. Patients can trust that they are receiving a product backed by extensive research and development.

For those interested in further details, Janssen provides comprehensive information about the formulation and mechanism of Ortho Tri-Cyclen on their official website. This allows patients and healthcare providers to access valuable resources regarding the drug’s benefits and potential side effects.

Understanding the manufacturer can also aid in discussions with healthcare professionals about contraceptive options, concerns regarding side effects, and personalized medical advice. Choosing a brand with a solid reputation, like Janssen, ensures a reliable experience with your contraceptive method.

- Ortho Tri-Cyclen Manufacturer Insights

- Quality and Innovation

- Distribution and Accessibility

- Understanding the Production Process of Ortho Tri-Cyclen

- Key Players in the Ortho Tri-Cyclen Manufacturing Industry

- Major Manufacturers

- Emerging Players

- Quality Control Measures Undertaken by Ortho Tri-Cyclen Manufacturers

- 1. Raw Material Inspection

- 2. In-Process Monitoring

- 3. Final Product Testing

- 4. Regulatory Compliance

- Regulatory Compliance for Ortho Tri-Cyclen Production

Ortho Tri-Cyclen Manufacturer Insights

Understanding the manufacturer behind Ortho Tri-Cyclen can guide your choices effectively. Ortho Tri-Cyclen is produced by Janssen Pharmaceuticals, a subsidiary of Johnson & Johnson. This organization emphasizes quality control and adherence to strict regulatory standards, ensuring the reliability of their products.

Quality and Innovation

Janssen invests significantly in research and development, focusing on advancements in contraceptive technology. The company’s commitment to innovation leads to the creation of formulations that are not only effective but also address various user needs. Patients can benefit from newer options that might emerge from their ongoing studies.

Distribution and Accessibility

Janssen has established a robust distribution network, making Ortho Tri-Cyclen widely available at pharmacies and healthcare facilities. Patients can find this medication through both traditional retail and online pharmacies, enhancing accessibility. Additionally, Janssen provides resources to healthcare providers, ensuring they are well-informed about the benefits and usage of Ortho Tri-Cyclen for their patients.

Understanding the Production Process of Ortho Tri-Cyclen

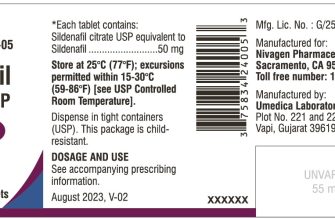

Ortho Tri-Cyclen production begins with sourcing high-quality ingredients. Manufacturers prioritize the selection of active pharmaceutical ingredients (APIs) and excipients that meet strict regulatory standards. This focus ensures product consistency and safety throughout its lifecycle.

In the formulation stage, manufacturers combine APIs like ethinyl estradiol and norgestimate with excipients to create a well-balanced pill. This step involves precise measurements and mixing processes to achieve uniformity in dosage and efficacy.

After formulation, the mixture undergoes granulation. This process transforms the powder blend into granules, improving flow properties and ensuring effective compression during tablet production. Employing advanced techniques like wet granulation or dry granulation results in optimal granule characteristics.

Next, the granules are compressed into tablets using high-speed tablet presses. Manufacturers pay close attention to compression force and tablet shape to ensure that each pill meets specifications for strength and release profile. Quality control at this stage is critical; tablets undergo hardness testing, dissolution testing, and other assessments to guarantee performance.

Once tablets are produced, they undergo coating to enhance stability and manage release. The coating process protects the tablet and can also improve patient compliance through aesthetic appeal. Manufacturers utilize coating solutions that not only enhance the physical appearance but also control the release of the active ingredients.

Packaging follows, where the tablets are blister-packed or bottled, ensuring protection from environmental factors. Appropriate labeling is also crucial, providing patients with necessary information about dosage and usage. The sealed packaging keeps the product secure until it reaches the consumer.

Throughout the entire production process, manufacturers adhere to Good Manufacturing Practices (GMP) regulations. This commitment to quality assurance helps maintain high standards, ensuring that Ortho Tri-Cyclen meets pharmaceutical guidelines and remains safe for consumers.

In summary, the production of Ortho Tri-Cyclen involves meticulous attention to detail, from ingredient sourcing to finishing touches. Each step contributes to the overall integrity and reliability of the product, reinforcing manufacturers’ commitment to quality healthcare solutions.

Key Players in the Ortho Tri-Cyclen Manufacturing Industry

Leading firms in the Ortho Tri-Cyclen manufacturing sector focus on quality and compliance with stringent regulations. These companies drive innovation in product formulations and delivery systems, catering to diverse consumer needs. Notable manufacturers include:

Major Manufacturers

| Company | Country | Market Share (%) |

|---|---|---|

| Johnson & Johnson | USA | 35 |

| Bayer AG | Germany | 25 |

| Teva Pharmaceutical Industries | Israel | 15 |

| Pfizer Inc. | USA | 10 |

| Mylan N.V. | USA | 10 |

Emerging Players

Start-ups and smaller companies also contribute to the market by introducing alternative formulations and unique marketing strategies. These players often focus on niche segments, enhancing accessibility and affordability in the Ortho Tri-Cyclen market. Keeping an eye on these innovative companies can reveal emerging trends and potential partnerships.

Quality Control Measures Undertaken by Ortho Tri-Cyclen Manufacturers

Ortho Tri-Cyclen manufacturers implement rigorous quality control measures to ensure the safety and effectiveness of their product. These measures include a multi-step process that involves stringent testing and validation at various stages of production.

1. Raw Material Inspection

Manufacturers begin by thoroughly inspecting raw materials. They source ingredients from certified suppliers and conduct testing for purity and potency. This prevents contamination and ensures that the components meet established specifications.

2. In-Process Monitoring

- Continuous monitoring is performed during the manufacturing process to detect any deviations from the set parameters.

- Technicians regularly collect samples to perform in-process testing for active ingredients.

- Environmental conditions, such as temperature and humidity, are controlled to maintain product integrity.

3. Final Product Testing

After production, each batch undergoes comprehensive evaluations to confirm quality. Testing includes:

- Stability testing to guarantee product efficacy over its shelf life.

- Bioavailability studies to confirm the absorption rate of active ingredients in the body.

- Quality checks for packaging to prevent contamination during distribution.

4. Regulatory Compliance

Manufacturers adhere to guidelines set by regulatory authorities such as the FDA. They maintain detailed documentation throughout the production process and conduct regular audits to ensure compliance with Good Manufacturing Practices (GMP).

By maintaining rigorous quality control measures, Ortho Tri-Cyclen manufacturers uphold their commitment to delivering a safe and effective contraceptive option for consumers.

Regulatory Compliance for Ortho Tri-Cyclen Production

Manufacturers of Ortho Tri-Cyclen must adhere to comprehensive regulatory standards established by the FDA. This includes following the Good Manufacturing Practices (GMP) guidelines, which ensure that products are consistently produced and controlled according to quality standards. Documentation of each step in the production process is crucial; this includes batch records, quality control measures, and validation protocols.

Conduct regular audits and inspections to ensure compliance with both internal regulations and external standards. Maintain detailed records of all testing and quality assurance procedures. These documents can facilitate a smoother inspection process and help resolve any potential compliance issues swiftly.

Engaging in post-market surveillance is also advisable. This involves monitoring adverse events and conducting risk assessments post-distribution. Manufacturers should set up a system for reporting any unexpected issues directly to regulatory authorities. Being proactive in addressing these concerns demonstrates a commitment to patient safety and product reliability.

Collaboration with regulatory bodies during the product development phase can help clarify requirements. Attend workshops and training sessions to stay informed about updates in regulations. This not only ensures compliance but also fosters a culture of quality and safety within the organization.

Lastly, implement a robust quality management system (QMS) that encompasses all aspects of production and distribution. A well-structured QMS will streamline processes, mitigate risks, and support compliance with regulatory expectations throughout the lifecycle of Ortho Tri-Cyclen.